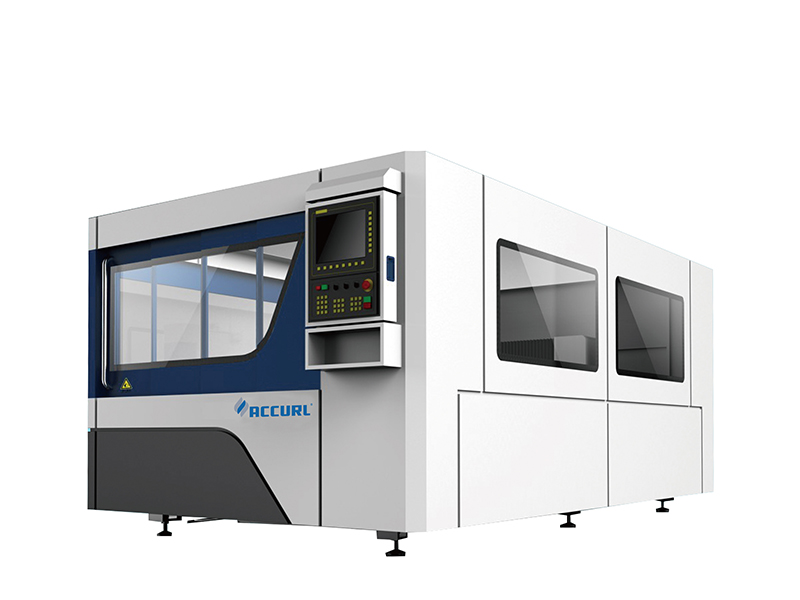

This షీట్ మెటల్ లేజర్ కటింగ్ యంత్రం, is ACCURL laser hardware industry according to the needs of research and development of thin మెటల్ ఫైబర్ లేజర్ కట్టింగ్ మెషిన్, the use ofgantry double drive structure,high precision rack rail drive,WEIHONG CNC laser cutting system,high precision collision Laser cutting head,reinforced welding bed, the whole stableandreliable, flexible operation and simple, high-speed drillingto achieve cutting function, professional cutting all kinds of sheet metal, precision accessories, hardware tools, gifts and other metal materials.

శీఘ్ర వివరాలు

అప్లికేషన్: లేజర్ కట్టింగ్

పరిస్థితి: క్రొత్తది

లేజర్ రకం: ఫైబర్ లేజర్

Applicable Material: Other

కట్టింగ్ మందం: పదార్థాలు

కట్టింగ్ ప్రాంతం: 1500 * 3000 మిమీ

కట్టింగ్ వేగం: 0-40000 మిమీ / నిమి

CNC లేదా కాదు: అవును

శీతలీకరణ మోడ్: నీటి శీతలీకరణ

Control Software: WEIHONG

Graphic Format Supported: Other

Certification: Other

అమ్మకాల తర్వాత సేవ అందించబడింది: విదేశాలలో సేవా యంత్రాలకు ఇంజనీర్లు అందుబాటులో ఉన్నారు

ఉత్పత్తి పేరు: ఫైబర్ లేజర్ కట్టింగ్ మెషిన్

Laser: RAYCUS

ఫంక్షన్: మెటల్ మెటీరియల్స్ కటింగ్

రకం: Fiber Lasr Cutting

Name: CNC fiber laser cutting machine

పని ప్రాంతం: 1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm

కీవర్డ్: ఫైబర్ లేజర్ కట్టింగ్ మెషిన్

Laser power: 750w

RAYCUS 750W CUTTING PARAMETERS

| మెటీరియల్ | గణము (మిమీ) | Cutting Speed(m/min) | గ్యాస్ |

| స్టెయిన్లెస్ స్టీల్ | 1 | 240 | N |

| 2 | 80 | 2 | |

| 3 | 25 | ||

| 4 | 18 | ||

| 5 | 10 | ||

| కార్బన్ స్టీల్ | 1 | 150 | O |

| 2 | 80 | 2 | |

| 3 | 70 | ||

| 4 | 30 | ||

| 5 | 25 | ||

| 6 | 18 | ||

| 8 | 15 |

రేకస్ లేజర్

a, For the best wavelength and best beam quality for metal processing, fiber lasers are the least expensive to cut.

b, Maintenance-free, long life, is 10 times longer life of CO2glass.

c,Laser with high stability, greatly reducing the requirements of laser quality control in operation.

d,Ultra-low cost, laser power consumption is only 0.5 to 1.5 degrees per hour ; blowing air can cut all kinds of sheet metal.

e, High-performance, imported factory-packaged fiber laser, stable performance, service life of up to 100,000 hours.

f,High speed, high efficiency, cutting sheets up to tens of met

ers per minute speed.

g, Good quality for cutting edge, small deformation, the appearance of a smooth, perfect.

MAX LASER

1.Lower power consumption

2.Lower cooling requirements

3.Higher spot quality

4.Lower consumption

5.High stability

6.High efficiency and low cost

High - precision digital anti - collision laser cutting head

The cutting head is equipped with extremely sensitive non-contact capacitive sensing device, can achieve a very stable Z-axis automatic tracking function, eliminating the uneven sheet on the cutting quality of the impact, thereby improving the product's pass rate.

The laser cutting machine is equipped with a focus lens to meet the needs of customers cutting the plate.

చిల్లర్

Using professional chiller by refrigerant control circuit, high precision temperaturecontroller control and display water temperature aromatically.

Running high efficiency low noise, The product internal water tank and pipe is made of stainless steel plate production, the external sheet metal parts are all made of electrostatic sprayingCoating, which can effectively prevent rust; Use clean water deionized water so as to improve the efficiency of laser equipment and life.

Applicable industries and materials

Advertising industry: stainless steel cutting, galvanized sheet cutting, cold plate cutting, carbon steel cutting, all kinds of advertising sheet metal, logo producing.

Industrial industry: aluminum, copper, titanium, metal hollow, handicrafts, stainless steel, cold plate, carbon steel, all kinds of metal sheet cutting.